An Epitome of The Sample

What is supply chain management? What is the relationship between supply chain management and organizational business objectives? What is the importance of an effective supply chain management in achieving the objectives of Nestle? What are the key drivers in achieving an integrated supply chain strategy in Nestle? You can find answers to these and more questions like these in this sample.

Introduction

Supply chain management has been defined as processes, which are interconnected with one another. They are linked with each other so as to provide a better and improved provision of goods and services to the customers. The members of supply chain start from suppliers who transfer the raw materials to a company. Then next is the manufacturer who produces the finished product and then comes the wholesaler or retailer through whom the goods reaches the final customer (Supply Chain, 2013). All members in a supply chain play a significant role. Today, as multi-nationals are operating globally in various countries and it is quite necessary for them to properly maintain and manage their supply chain. Logistics is the transport of finished goods to the various associates of the supply chain so that retail stores of any company are never out of stock. In this project, case of Nestle is studied and how it manages its supply chain and logistics is also explored. It will be explained that how the company implements the changes in its logistics and satisfied customers.

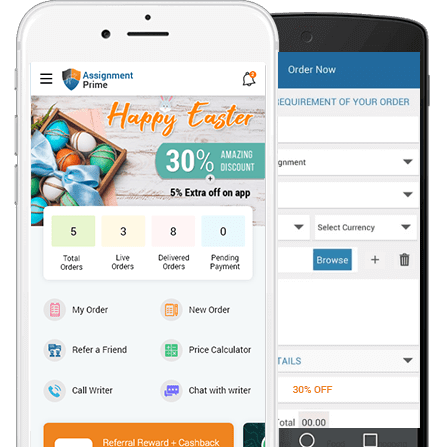

Assignment Prime is an online assignment writing service provider which caters the academic need of students.

Get Best Pricing Quotes Free Samples Email : help@assignmentprime.com Order NowLO1:Understand The Relationship Between Supply Chain Management (SCM) And Organisational Business Objectives

LO1.1 Importance of effective supply chain management in achieving organizational objectives in Nestlé

The main aim of Nestle is to satisfy its customers by making available all goods produced by it. They should have the feeling that the company is running out of stock. Also, it has to see that time taken for transportation of products is lessened and they are reached quickly. All these objectives were established by maintaining a proper supply chain. With the help of it, nestle was able to make a link between its two biggest distribution hubs in the United Kingdom, which are situated in Bardon York and in Leicestershire. In addition to this, another objective of the company was to establish a single customer service center in New York. This was also accomplished with the help of logistic and supply chain management, which help the company to know about the status of each of its products (Logistics / supply chain, 2013). This means that the company was made aware that which of its goods are in maximum demand and accordingly production can be done.

This also helped Nestle to improve upon its services and that too without increasing its costs. The company managed its supply chain in such a manner that it was able to have control of its costs incurred also.

LO1.2 Link between supply chain management and business functions in Nestlé

The important business functions associated with nestle is to focus on its crucial areas as that of sales and marketing along with financial. Also, it has to work and produce new products according to the changing needs of the people. In order to increase its sales, Nestle is required to focus on supply chain and ensure that the products are reaching on time at all the retail stores. Also, with the help of proper management it is able to reach its customers in a better way and provide its offerings to them (The Nestlé Supplier Code, 2010).

The supply chain is carried on at two levels, that is, one is from a place of manufacturing to the distribution center of Nestle and then next is from the center to the retail stores, which sell the goods. This link between supply chain and the business functions help the company to understand the demands and work according to that.

LO1.3 Key drivers for achieving an integrated supply chain strategy in Nestlé

The key drivers behind any supply chain help the entire organization to achieve its objectives in an effective manner. For Nestle, the factors, which help it to achieve a well balanced supply chain are firstly, all members of the supply chain. It means that a proper coordination among all of them is helpful in maintaining it (Nestlé Re-balancing Case Study, 2013). By achieving this, the company is able to keep itself aware of the changes happening in the market. Is also knows that which are of its products are not liked and what alterations are needed to be done. By the proper flow of information from one constituent to another change can be implemented immediately.

Another factor that assists in the formation of a well managed supply chain is synchronization of all its individual processes of the unit. This helped the organization to focus only on the demands of the targeted customer. In addition to this, the integration of all systems of information in an orderly manner also leads to an efficient supply chain (Christopher, 2010).

LO2: Be Able To Use Information Technology To Optimize Supplier Relationships in An Organisation

LO2.1 Effectiveness of strategies used by Nestlé to maintain supplier relationships

In the existing competitive scenario, every person or group involved in any kind of business want to earn profits and be in a situation of a win – win. Same is with nestle, which is adapting changes to increase its profitability. This is possible only if it is able to maintain healthy and positive relations with its suppliers and the company is successful in doing so. According to the case study, Nestle also maintained good terms with the constituents so that it is able to increase its sales (Chopra and Meindl, 2009).

It is the result of this relationship that the products of Nestle reach the customers whenever required. Also, they are the retailers and wholesalers who make the company aware of the demands of the products according to the different demographic profile of the consumers. This helped the company to know how to target the customer group and how it should produce in order to satisfy them (Chaffey, 2009). Since the main aim of the company is to attract more and more customers and nestle is able to achieve the target shows the effectiveness of relationships with suppliers

LO2.2 Information technology to create strategies to develop Nestlé’s relationship with its suppliers

Fast and improved systems in the information technology have now become as one of the greatest means through which a company can maintain all its processes in an effective manner. Nestle also makes use of technologies in information processes, which not only help the company to carry on its activities efficiently but also to develop good relation with the suppliers and other members of the supply chain. For this, Nestle, keep a record of its daily transactions and this data is then distributed to all constituents of the supply chain. This will make them aware of the activities going on in the company (Turban and et. al., 2009). It makes use of an electronic data interchange with the help of which a common operating system is implemented and data is being transferred in a standard format. This ensured an easy flow of information from one end to the other.

Nestle also uses an electronic integration, which is IT enabled and help the company to bind it with the suppliers so that any kind of information and updates can be transferred quickly. This also leads to an establishment of long term relation with the suppliers (Weth, 2007).

LO2.3 Systems to maintain Nestlé’s relationship with its suppliers

Advances in information technology are provided with various systems to all companies with which they can now able to sustain their relationships with suppliers. For maintaining an accurate coordination between Nestlé and its distribution centers at Bardon and Leicestershire it make use of SAP (Systematic Analysis and Program) enterprise resource planning system. This helped the company and suppliers to remain connected (Harrington, Boyson and Ccorsi, 2010). With this, the flow of information became easy.

In addition to this, Nestlé’s implemented an Autostore warehouse management system (WMS) for running and managing the movements of products at both of its distribution centers. This way all of data can be passed on from the warehouse to the suppliers and vice versa. An opportunity is created for all with which the management can communicate without any kind of hassles. The company will get to know about concerning the major issues in relation to the sales which will help it to take necessary steps to increase profitability (Kotzab and Bjerre, 2005). All the systems help the company and suppliers to do all deals fairly and negotiations can be carried on in an efficient manner. Satisfaction of suppliers will result into healthy relations with them.

LO3 Understand The Role of Information Technology in Supply Chain Management

LO3.1 Assessment of how information technology could assist integration of different parts of the supply chain of Nestlé

When the information is transferred freely and regularly all members of the supply chain as well as of a company are coordinated into one unit. Though this, all of them have sufficient knowledge to carry on the required operations and work in order to gain maximum satisfaction from the customers. It is the advancements in the information technology that it is possible to adapt an integrated system through which knowledge can be transferred. This enables all parts of the supply chain of Nestle to remain together (Stadtler and Kilger, 2007).

By making use of electronic data interchange, nestle maintains a link among all so that all of them are interconnected with one another. Through this, a member at the customer end can inform about the alterations in patterns of demand of public and immediately the solution can be thought upon by the management of the company. This will also help to maintain a transparency and trust building among all members since all negotiations will be done in front of everyone and known by all (Defee and et. al., 2010).

LO3.2 Evaluation of how information technology has contributed to the management of the supply chain of Nestlé

Information technology has not only helped Nestle to integrate all its members of the supply chain but also assisted in the coordination of internal management. Since, the means of conveying information have increased, which have become faster, it is now possible for Nestle to reduce its costs. The new techniques have not only caused an increase in the number of transactions but have also led to an increment in the negotiations with the suppliers. This eventually satisfies them which are ultimately beneficial for the company. The speed with which the information is passed has caused a reduction in the number of human errors through which the business operations run faster without being hampered (Evaristo and Zaheer, 2012).

Today, the competitive market is quite dynamic and unpredictable but with the use of information technology it is possible to predict changes up to a good extent. Also, all members of the supply chain can be informed about the change which is easy for everyone to respond to the changes and compete in the market (Nemoto and Rothengatter, 2012).

LO3.3 Assessment of the effectiveness of information technology in managing the supply chain of Nestlé

The fact that Nestle has adopted an efficient technique of transfer of information to manage its supply chain is seen from the ready availability of products. The response of the customers is also positive regarding the products. Intranet and web distribution has made it possible for all members of the supply chain to know about the changes or delays possible regarding a product. This has lead to the maintenance of an integrated form of supply chain into a single unit through, which everyone is informed regularly. This assists in the reduction of risks to the company also (Kalubanga, 2012).

Nestle can revise its supply chain periodically, if required, without wasting much of time and resources by making use of information technology. In addition to this, it can form a customer base globally and in multiple units in not much time. The costs of Nestle are reduced because all supplies and receive orders can now be given electronically along with the payments which is not only secured but also saves a lot of manpower which can be used alternatively (Meehan and Muild, 2008).

LO4 Understand The Role of Logistics And Procurement in Supply Chain Management

LO4.1 The role of logistics in supply chain management in Nestlé

An important part of the supply chain is its logistics. It is the process which takes into account carrying of goods from the warehouse of a company to wholesalers or retail stores. The manner and the means through which finished products are transferred towards the required destination are known as logistics. The aim of this department is to provide mobility and delivery of products timely which will add to a flexible business environment. Nestle has done a lot of hard work on its logistics to reach the company objectives (Zachariassen and Liempd, 2010). With the help of it, it is able to bring into operation the pallet loads of composite nature in the whole of the UK. In addition to this, it has also installed it with beverages and confectionery within two main distribution hubs through two vehicle fleets.

According to the case study, with the help of its consultant of supply chain, Nestle is working on ‘Total Logistics’ for many years. This has helped the company to resolve appreciable strategic issues which require concern. It now believes in delivering smaller volumes of goods which lead to a reduction of costs (Croom, 2005).

LO4.2 Evaluation of procurement practices in Nestlé

In order to satisfy that all operations of Nestle are being run in an effective manner, practices of the procurement need to be followed. It is the process through which identification of high-quality goods is being done. With it, proper supplies are known which will be able to transfer the products of the company in a proper manner. The process of procurement also involves purchasing and sourcing activities of an organization (Sari, 2007).

Within this process, nestle has to keep a track that whether all its members of the supply chain are working according to the standards of safety and quality of the company or not. If the suppliers are aware of it they will deliver such raw materials, which are favorable for the users. Procurement practices of nestle are such that it has identified all its suppliers and distributors carefully who are capable of running the business properly. It also takes into note that the means through which products are supplied to the retail stores are environmentally friendly and does not harm anyone (Christopher and Lee, 2004).

LO4.3 Factors that must be considered when improving logistics and procurement practices in Nestlé

There are various means through which Nestle can improve over its supply chain and logistics along with the procurement practices. For this, it is to be ensured that a transparency is maintained during all negotiations it deals with its members of the supply chain. This will help them to know that they are not cheated and are treated fairly. Eventually, this will result in maintenance of proper coordination among all and everyone will give their best services. It will also cause to have a cost effective system (Zhexembayeva, 2010).

In addition to this, nestle needs to pay attention that all business processes run in an efficient way and rules are being followed or not. In order to carry out the practices of procurement effectively it is necessary for the company to check that its operations comply with the set standards and regulations (Tarn, Yen and Beaumont, 2002).

LO5 Be Able To Plan A Strategy To Improve An Organisation’s Supply Chain

LO5.1 A strategy plan for improvement of Nestlé’s supply chain

It is important for any organization to strategically plan a supply chain for it and how it can be managed properly. Firstly, there is a need that Nestle implement effective techniques of communication within the company, which can ensure to provide a free flow of thoughts and options. If information can be transferred quickly without taking much time then all will be updated immediately. This will help the company to have an insight into the market conditions according to which it has to carry on its operations (Vachani and Post, 2012). Secondly, Nestle should work on its business processes and operations because if this is improved then only timely delivery of products can be made possible.

Then next factor to be considered is the management of risk. It is the supplier’s duty to keep records of the demands of the customers and make the company aware. Also, it should inform about the changes in the choice of the consumers. If a healthy relationship is not maintained by the suppliers then this will not be possible so there is a need for the company to work on this aspect (Sandelands, 1997).

LO5.2 Assessment of how a supply chain improvement strategy will benefit overall business performance in Nestlé

If a proper strategy is implemented for improving the supply chain of Nestle it will undoubtedly improve the overall performance of the business in the following ways-

Through this, delays regarding the fulfillment of orders by the retailer on the warehouse can be reduced to a greater extent.

- Negotiations with the suppliers can be done faster and transactions can also be improved.

- With the improvement in supply chain costs will be reduced and more resources can be employed for useful purposes (Guffog and Wadsley, 1999).

- A better collaboration and coordination among members of the supply chain is established with the help of improved strategy of the supply chain.

Conclusion

Supply chain management and logistics not only form an important part of any company but is also the main backbone of it. By administering them in a controlled manner, it is possible to achieve an overall efficiency and utilization of resources can be done in a more organized way.

Our professional assignment writing help experts have written more such samples that you can have a look at in the sample section!

References

- Logistics / supply chain. 2013. [Online]. Available through

- Nestlé Re-balancing Case Study. 2013. [online]. Available through

- Products & Services. 2013. [online]. Available through

- Supply Chain. 2013. [Online]. Available through

- The Nestlé Supplier Code. 2010. [pdf]. Available through

- Chaffey, D., 2009. E-Business and E-Commerce Management: Strategy, Implementation and Practice. 4th ed. Financial Times/Prentice Hall.

- Chopra, S. and Meindl, P., 2009. Supply Chain Management: Strategy, Planning and Operation. 4th ed. Pearson Education.

You may also like you read